GroundBraker

New innovative braking system for mobility aids.

Main Roles

Electronics/Prototyping Lead

The prototype was developed in association with MISA as part of a undergraduate group design project.

What I did

- Sensor Design.

- Motor Control via Arduino.

- Rapid Protoyping.

- User Testing.

A link to the project website can be found below!

Project Brief

Design a product to aid the ageing population...

At the beginning of this project we were given a very broad project brief , to design something to aid the ageing population of Ireland. This gave us the freedom to go out and talk to our user base to find out what their problems were so that we could engineer a solution for them. I got us to engage with our entire stakeholder base from doctors and nurses, to the ederly and their carers to find the real problems in their life that needed fixing. The problem that we identified was reliability of mobility aid brake.,They would often wear down to the point that they could no longer provide support for user and care facilities were spending a lot of money throwing old mobility aids out as there was no easy way replace them. .

Solution

Two systems. Dynamic disc braking. Smart parking brake.

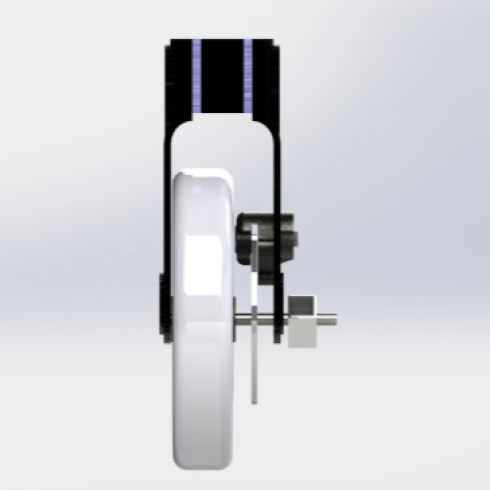

The dynamic braking system was based off the disc brakes found on mountain bikes. The benefits were two fold, it both reduced the force required to apply the brakes dramatically and made it easier to replace them. The Smart braking system solved the slipping problem. Th milled surface of the disc would guide the pin into the hole locking the wheels in position and the brake was activated by a large ergonomic button with safety sensors in place to prevent accidental deployment.

Design Development

Mechanical Design and Prototyping

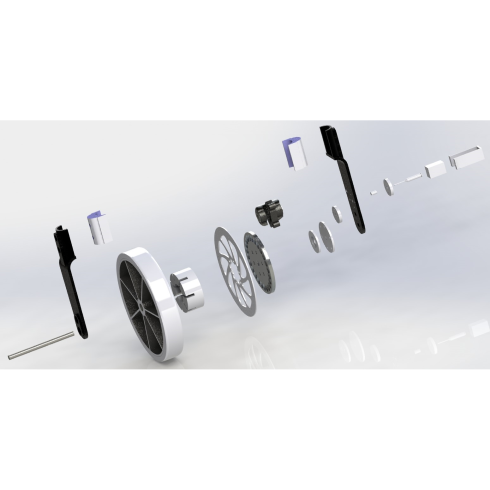

Mechanical design of the system began by creating a full 3D model. For purposes of the prototype we were adapting the braking system of an old mobility so spacers had to be manufactured to allow for the installation of the new disc brakes (retrofitted from a bicycle). Most of the new parts were 3D printed apart from the parking brake components which were milled out of aluminium to ensure their strength. Finite Element Analysis was also performed on the systems to ensure that the new parts would not break under normal operating conditions.

Electronics and Control

An Arduino was used as the controller for the parking brake system. It operated two solenoid actuated pins that upon activation would engage with the wheel and stop the mobility aid. As a safety precaution a motion sensor was added in the form of a hall effect sensor and magnet inset into the wheel that could sense if the aid was move and stop the parks from deploying. The system also used the inbuilt EEPROM to stored the last brake state so that in the case of a power outaged the brake would not disengage suddenly. Throughout the whole design process to the user and their needs were kept at the forefront of out thoughts. With each change or new feature we added we tested it with our endusers, ensuring that all of our choices were well informed.